I must suck at reloading I can't even come close to.0002. I can't even get .0007.

Shep

[/QUOTE Let me please qualify my following statements.

This web site has a combined wealth of knowledge as there are many individuals who freely and openly give their worthy advise. This truly is a godsend for anyone who is interested in the shooting sports and to the further expansion their of.

I for one would like to thank each and every one of you for your contributions !

Now down to the business at hand!

Using the Horandy Concentricity Tool and by making adjustments you certainly can bring your bullet to case mouth run out down dramatically everything else being equal.

Without going into details ( see U tube videos ) after you have deprimped , cleaned , ( don't forget the primer flash holes on virgin brass ) dried , FL resized , shoulder bumped , trimmed , champhered your brass , annealed and finally neck turned your virgin brass you are ready to completely assemble your ammunition.

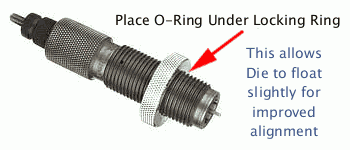

Once this has been accomplished simply place hand load into the Horandy Concentricity Tool , and using the indicator which will be making a light contact ( use the supplied rubber O rings for the indicator shaft in order to accomplish this ) somewhere on the bullets Major O.D.( before your taper starts) , rotate the bullet and notice the high and low readings as you zero out your dial on the minus or low side.

Now again rotate the bullet , stop at your lowest reading which would be the minus side and turn the nylon adjustment screw which will be now resting on the bullet just before it's Ojive past your newly indicated zero, stopping on the plus side say .010" to allow for spring back and back off the adjustment screw allowing clearance on the bullet itself ( again refer to U-Tube Videos)

Now while indicating the bullet in its cradle notice your run out.

If it has changed again zero at the mean dimension while turning the bullet to indicate the lowest or minus reading and repeat the procedure until you have achieved your minimum amount of run out and you are good to go !

With a little hands on you will constantly be producing rounds that will be in the .0002" - .0007" T.I.R. range, noting most factory ammunition is between + -.001" T.I.R. ( that is what they accept as passable as they produce many thousands of rounds each day) You on the other hand are only producing ammunition in small controlled lots and therefore can afford to be particular !

Please note there are a lot of other variables to contend with as well.

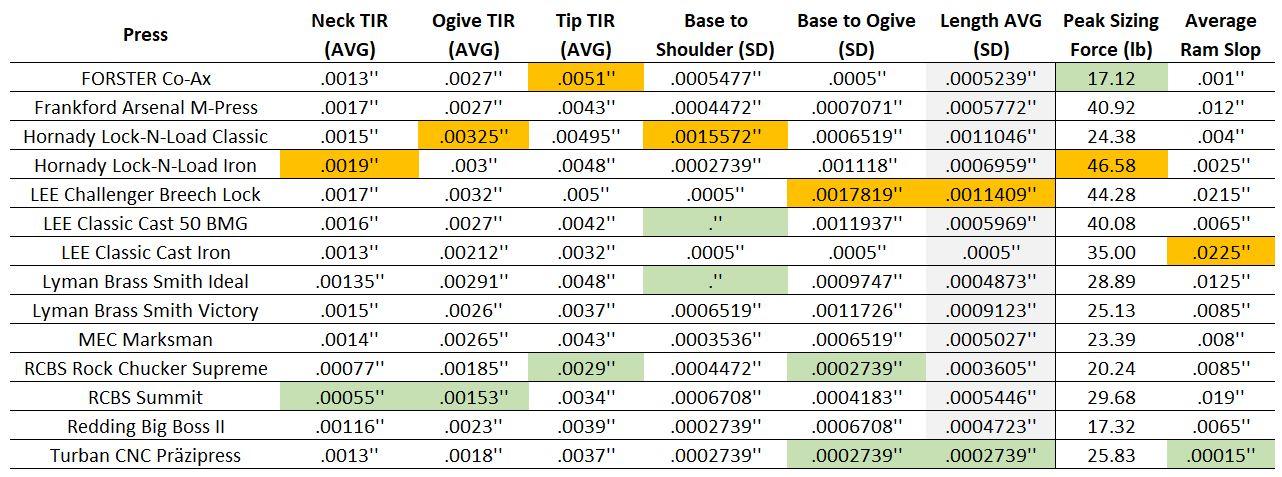

Wear or runout on presses, dies, shell holders/ shell plates ,as well as grit (as noted in my earlier post) can play hell with your reloading !

Each item in turn must be checked , and either replaced or otherwise ruled out until you are satisfied that you are producing the best handload possible.

To that end there are many tools that can help you to accomplish that task. Do your homework and research before you decide on any future needs.

Bear this thought in mind !

By purchasing a well known brand of Reloading Press , one with an established track record and the best reloading dies that you can find you are more than 1/2 way home !

I.M.H.O. some items are just whims, while others are necessary in order to help you achieve your goals.

My Additional 2 Cents Worth !