One of my sidelock (detectable) needs to be opened up. The barrel is not firing. I here a click, BUT. I think I need to get inside. But my screwdrivers (Wheeler) kit are too fat. The screws look like they need a screwdriver bit is like a knife. I don't want to screw up. Is there a good set made for fine screws or should I take it to a gunsmith?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fine screwdrivers or take to a gunsmith?

- Thread starter Marplot

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

LuvDog

Well-Known Member

I’d probably start grinding away at a screw driver and try it myself.

The worst thing is to have the tip of a driver slip and twist the slot in the screw or even worse scratch the fire arm. I personally like Hollow Ground Flat drivers that fit perfectly in the slot, but here are some reviews from the internet.

www.cnccookbook.com

www.cnccookbook.com

World's Best Screwdriver Set [Tested & Reviewed by a Machinist]

Who makes the world's best screwdrivers and best screwdriver sets? This in-depth article covers 8 brands you should consider for your needs.

ShtrRdy

Well-Known Member

You can buy individual bits that are sized for the slot from Brownell's.

I tried Grace and broke Grace several times on stubborn Auto-5s, went to Brownell's tips and you'll bend/distort them long before you break them.

Good bit driver that you can remove the handle on and slide a short 1/4" boxed end wrench on or one of these for a really stubborn screw. Also use plenty of Kroil on the screws before you start.

Felo T-handle, German made and stout

Good bit driver that you can remove the handle on and slide a short 1/4" boxed end wrench on or one of these for a really stubborn screw. Also use plenty of Kroil on the screws before you start.

Felo T-handle, German made and stout

Appears to be very fine, looks to be quite shallow as well but can't tell for sure.

Hollow ground vs tapered isn't going to make much difference if the slot is as shallow as the picture makes it look. If you have a fine bit of the proper width and just slightly thicker than needed, I'd start with LuvDog's suggestion. If you're good with the grinder you can grind parallel sides, just make sure you don't get it too hot and destroy the temper. You can tell by feel if the tip is making a proper fit from the lack of play. First- put a drop of Kroil on the slots and give it some soak time. Even with a perfectly matched, hollow-ground bit you can't put a lot of torque on a screw with a shallow slot-if it resists I'd keep working with Kroil and light heat from a heat gun or hair dryer.

No reason to take it to a smith unless he lives next door- they're just screws. If you don't have or can't grind the correct size tip, purchase it.

Hollow ground vs tapered isn't going to make much difference if the slot is as shallow as the picture makes it look. If you have a fine bit of the proper width and just slightly thicker than needed, I'd start with LuvDog's suggestion. If you're good with the grinder you can grind parallel sides, just make sure you don't get it too hot and destroy the temper. You can tell by feel if the tip is making a proper fit from the lack of play. First- put a drop of Kroil on the slots and give it some soak time. Even with a perfectly matched, hollow-ground bit you can't put a lot of torque on a screw with a shallow slot-if it resists I'd keep working with Kroil and light heat from a heat gun or hair dryer.

No reason to take it to a smith unless he lives next door- they're just screws. If you don't have or can't grind the correct size tip, purchase it.

sable tireur

Well-Known Member

- Joined

- Oct 8, 2010

- Messages

- 3,542

I don't want to screw up. Is there a good set made for fine screws or should I take it to a gunsmith?

Please note, the two screws shown are typical of high end side locks. These are engraved and should not be trifled with unless you have the experience and the proper tools.

The proper tools are referred to as TURN SCREWS which I pointed out in the original post. These are matched and fitted to these screws so there is no chance of movement to result in a damaged screw head and the engraving. Damage one of these then try to find someone to replace it AND engrave it.

The simple solution is to find a gunsmith with the expertise to remove these screws then turn the project over to you if you are competent to manage the fix. These gunsmiths are few and far between especially nowadays.

Lacking a gunsmith with the required experience and the proper tools, try to find the best TURN SCREWS you can and buy them. Then you can have at the screws knowing you have the proper tools. This is not a game for novices.

Best of luck with your project!

pdavitt

Well-Known Member

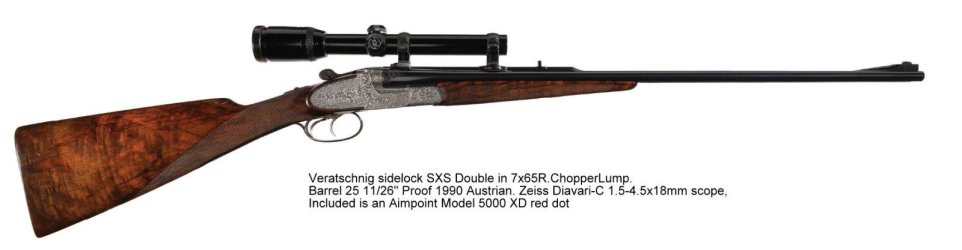

You didn't state the maker's name, or if it is a collectable piece. From the single photo it looks high end. I was lucky enough to inherit a Westley Richard's double rifle from my grandfather. If anything goes wrong with it, the only place I would send it is to Westley Richard's in the UK.

I got the wonderful Real Avid screwdriver set. I very gently took out the engraved screws. #1 is short, #2 goes all the way though. #3 is too shallow head to even try. I suppose that #2 could hold the two sidelocks together. BUT I was too nervous to proceed. I have taken off sidelocks in my flintlock weapons, but this firearm (Pictures) scares me. Could I take off one and have it go "SPROING!"

So I very gently replaced the engraved screws as they were. I had not read Sable Tireaur's post about "TURN SCREWS" (I would not have done so) but all is well. I know a gunsmith nearby and he can look at it in about a week. If he does not feel comfortable I am also reaching out to friends in the "German Collector Gun Association" for the right guy.

Here is the auction definition

"E. VERATSCHNIG.9173.AUSTRIA" marked on the sunken portion of the rib, fixed gold centerlined rear sight and German style claw mounts holding a Zeiss Diavari-C 1.5-4.5x18mm scope in engraved rings on the engraved rear quarter rib, import mark under forend, wedges of scroll at either breech, 1990 dated Austrian proofs, and chambers with automatic ejectors

So I very gently replaced the engraved screws as they were. I had not read Sable Tireaur's post about "TURN SCREWS" (I would not have done so) but all is well. I know a gunsmith nearby and he can look at it in about a week. If he does not feel comfortable I am also reaching out to friends in the "German Collector Gun Association" for the right guy.

Here is the auction definition

"E. VERATSCHNIG.9173.AUSTRIA" marked on the sunken portion of the rib, fixed gold centerlined rear sight and German style claw mounts holding a Zeiss Diavari-C 1.5-4.5x18mm scope in engraved rings on the engraved rear quarter rib, import mark under forend, wedges of scroll at either breech, 1990 dated Austrian proofs, and chambers with automatic ejectors

Attachments

PopNFresh

Well-Known Member

the front one by the fences is the retaining screw, should go into action. each lock will have one.

long one is the through screw that flexes the locks into the proper position. it goes through one lock and threads into the other.

the third "screw" is the end of the tumbler going through the lock, the line is a cocking indicator. It's you're hammer which is kept in proper alignment between the hole in the lock and the lock's bridle. it won't come out until the guts do

long one is the through screw that flexes the locks into the proper position. it goes through one lock and threads into the other.

the third "screw" is the end of the tumbler going through the lock, the line is a cocking indicator. It's you're hammer which is kept in proper alignment between the hole in the lock and the lock's bridle. it won't come out until the guts do

PopNFresh

Well-Known Member

I'm betting on busted firing pin but who knows.....