300 Remington Ultra Magnum ABS Barrel Review

By Michael Eichele

My buddies Heath and Jess and I were on our way out of a large valley in the Chugach mountains after I harvested a 55" bull moose with the 300 RUM that I had built specifically for this moose in this valley. The rifle was built around a Remington 700 bolt action and McMillan stock. My barrel choice was a 27.25 Lilja 12x in NBRSA HV taper. The scoped rifle weighed in at 16.5 pounds with ammo and bipod. After packing this rifle into the high steep country to access this remote valley and back up and over lugging this chunk of steel around, I realized how much my upper body was screaming at me. I decided then and there to do something to lighten this rifle up.

After a brief phone discussion with Mike at ABS barrels I was sold. I paid for it right there over the phone. Mike stated that the turnaround time was typically about 3 months but he said he had one barrel in stock due to a deal that fell through that was exactly what I was looking for and that he could get it to me with in two weeks.

To make a long story short and without going into details, one year later, I finally received my barrel. Now for the good news. Mike threw in a titanium muzzle brake custom built to my exact specifications for free for my trouble. Upon getting her back from my rifle smith, I gave her a good cleaning from the test firings and was amazed that there was absolutely NO copper to be removed.

Day One At The Range

I never judge a rifle based on my first day at the range. There are too many mental distractions and hopes to really concentrate on the task at hand. However, there were 3 groups that showed signs of real promise and with excellent hunting bullets to boot! I was getting really excited. The very first group was right at 1 MOA. A couple of groups later it shot a .75 MOA group. The last group was 0.4 MOA.

Load notes:

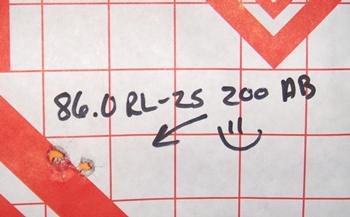

Best load tested on day one.

86.0 RL-25 with the 200 ACCUBOND

Velocity 1: 2941, Velocity 2: 2916, Velocity 3: 2942

Accuracy = 0.4" @ 100 yards.

Day Two At The Range

Day two was really exciting. I only fired 2 groups and went home. I only fired two because I shot the lowest charges I had and decided that if they weren't max loads, they were max enough. The first group was .486" at 100 yards. The second group was .241".

Load notes:

Load one: 91.0 RL-25 with the 200 ACCUBOND

Velocity 1: 3236, Velocity 2: 3177, Velocity 3: 3191

Accuracy = 0.486" @ 100 Yards. Perfect extraction, primers look good, no ejector marks.

Load two: 95.0 RL-25 with the 180 ACCUBOND

Velocity 1: 3412, Velocity 2: 3342, Velocity 3: 3377

Accuracy = 0.241" @ 100 Yards. Perfect extraction, primers look good, no ejector marks.

Day Three At The Range

I am not one to settle for high extreme spreads. Later I learned that my case necks were in need of annealing and that RL-25 actually gave me the lowest ES with proper neck tension. Nevertheless, I had to see what H1000 and RETUMBO would do.

Load notes:

Load one: 95.0 RETUMBO with the 180 ACCUBOND

Velocity 1: 3340, Velocity 2: 3315, Velocity 3: 3330

Accuracy = 0.656" @ 100 Yards. No pressure signs.

Load two: 91.0 H1000 with the 180 ACCUBOND

Velocity 1: 3144, Velocity 2: 3154, Velocity 3: 3135

Accuracy = 0.6" @ 100 Yards.

One Week Later. First 300 Yard Session

It was time to move on from 100 yards to 300 yards. The first 300 yard group was promising but not great.

Load notes:

Load one: 95.0 H1000 with the 180 ACCUBOND

Velocity 1: 3276, Velocity 2: 3255, Velocity 3: 3279

Accuracy = 2.293" @ 300 Yards.

Load two: 96.0 RETUMBO with the 180 ACCUBOND

Velocity 1: 3351, Velocity 2: 3352, Velocity 3: 3375

Accuracy = 3" @ 300 Yards.

Second 300 Yard Session

It was now time to re-test the best load.

Load notes:

Load one: 95.0 RL-25 with the 180 ACCUBOND

Velocity 1: 3485, Note that the bolt was stuck and had to be tapped open. There was a major extractor mark and cratered primer. Velocity 2: 3437, note that extraction was easier but sticky. Extractor mark as well. Velocity 3: 3395, note that the extraction was easier yet but still a bit sticky.

Accuracy = 3" @ 300 Yards.

Load two: 96.0 H1000 with the 180 ACCUBOND

Velocity 1: 3345, Velocity 2: 3316, Velocity 3: 3301

Accuracy = 2.155" @ 300 Yards.

Load three: 96.5 H-1000 with the 180 ACCUBOND

Velocity 1: 3373, Velocity 2: 3344, Velocity 3: 3380

Accuracy = 2.082" @ 300 Yards.

It is noted that this load was hot due to slightly sticky extraction and ejector marks.

Load four: 90.0 H-1000 with the 180 E-Tip

Velocity 1: 3238, Velocity 2: 3227, Velocity 3: 3218

Accuracy = 3" @ 300 Yards.

Something is not right

This certainly isn't the end of my development, but there are enough load notes above to gauge the overall performance of this rifle. It is at about this stage that I feel like something dramatic is wrong. It seems as if my pressures are going up with the same loads from day to day. I start dropping powder charges lower and lower and they still seem hotter and hotter. Also it starts to copper foul really bad. After a total of between 200 and 250 rounds fired, the barrel settles down and pressures and velocity appear to become consistent.

Now I start the load development over. To make a very long story short, this rifle will no longer shoot the 200 ACCUBOND with any degree of accuracy and no matter what powder or the charge weight, extraction is tough and the brass is beat up. I have fired it with H50 BMG with as little as 3000 FPS and the extraction and brass are not good. I have also tried using RL-25 and H1000 with even more horrid results. The 180 ACCUBOND doesn't act as bad but acts very similar to the 200. Now after its settle down mode, the loads it likes the best is the 220 SMK over 90.0 H50 BMG at 2850 FPS, the 208 AMAX with 93.0 H50 BMG at 2925 FPS, the 190 Hornaday BTSP atop with 88.5 grains of RL25 and the 178 AMAX with 90.0 H-1000. All will hold .5 MOA or better with the 220, 208, 178, especially the 208 doing so the best. The 190 averages 0.5 to 0.6 MOA and sometimes does better and sometimes hits the 1 MOA mark.

My Worst Fears Are Realized

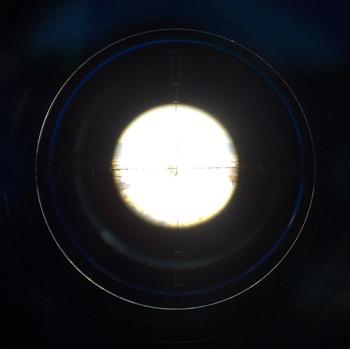

I took my barrel to a local smith the other day along with the old Lilja barrel I still have that has over 1000 rounds through her. I compared the throat of each side by side as well as several inches up the barrel. To my surprise, the ABS looks almost identical to the Lilja with not even half as many rounds through it. At this point, it become clear as to why it copper fouls so bad now and won't shoot the same as it did in the beginning with the same loads. I only had between 60-65 shots through it when I noticed the major changes. The throat was somewhat cooke

Article Tools

By Michael Eichele

My buddies Heath and Jess and I were on our way out of a large valley in the Chugach mountains after I harvested a 55" bull moose with the 300 RUM that I had built specifically for this moose in this valley. The rifle was built around a Remington 700 bolt action and McMillan stock. My barrel choice was a 27.25 Lilja 12x in NBRSA HV taper. The scoped rifle weighed in at 16.5 pounds with ammo and bipod. After packing this rifle into the high steep country to access this remote valley and back up and over lugging this chunk of steel around, I realized how much my upper body was screaming at me. I decided then and there to do something to lighten this rifle up.

After a brief phone discussion with Mike at ABS barrels I was sold. I paid for it right there over the phone. Mike stated that the turnaround time was typically about 3 months but he said he had one barrel in stock due to a deal that fell through that was exactly what I was looking for and that he could get it to me with in two weeks.

To make a long story short and without going into details, one year later, I finally received my barrel. Now for the good news. Mike threw in a titanium muzzle brake custom built to my exact specifications for free for my trouble. Upon getting her back from my rifle smith, I gave her a good cleaning from the test firings and was amazed that there was absolutely NO copper to be removed.

Day One At The Range

I never judge a rifle based on my first day at the range. There are too many mental distractions and hopes to really concentrate on the task at hand. However, there were 3 groups that showed signs of real promise and with excellent hunting bullets to boot! I was getting really excited. The very first group was right at 1 MOA. A couple of groups later it shot a .75 MOA group. The last group was 0.4 MOA.

Load notes:

Best load tested on day one.

86.0 RL-25 with the 200 ACCUBOND

Velocity 1: 2941, Velocity 2: 2916, Velocity 3: 2942

Accuracy = 0.4" @ 100 yards.

Day Two At The Range

Day two was really exciting. I only fired 2 groups and went home. I only fired two because I shot the lowest charges I had and decided that if they weren't max loads, they were max enough. The first group was .486" at 100 yards. The second group was .241".

Load notes:

Load one: 91.0 RL-25 with the 200 ACCUBOND

Velocity 1: 3236, Velocity 2: 3177, Velocity 3: 3191

Accuracy = 0.486" @ 100 Yards. Perfect extraction, primers look good, no ejector marks.

Load two: 95.0 RL-25 with the 180 ACCUBOND

Velocity 1: 3412, Velocity 2: 3342, Velocity 3: 3377

Accuracy = 0.241" @ 100 Yards. Perfect extraction, primers look good, no ejector marks.

Day Three At The Range

I am not one to settle for high extreme spreads. Later I learned that my case necks were in need of annealing and that RL-25 actually gave me the lowest ES with proper neck tension. Nevertheless, I had to see what H1000 and RETUMBO would do.

Load notes:

Load one: 95.0 RETUMBO with the 180 ACCUBOND

Velocity 1: 3340, Velocity 2: 3315, Velocity 3: 3330

Accuracy = 0.656" @ 100 Yards. No pressure signs.

Load two: 91.0 H1000 with the 180 ACCUBOND

Velocity 1: 3144, Velocity 2: 3154, Velocity 3: 3135

Accuracy = 0.6" @ 100 Yards.

One Week Later. First 300 Yard Session

It was time to move on from 100 yards to 300 yards. The first 300 yard group was promising but not great.

Load notes:

Load one: 95.0 H1000 with the 180 ACCUBOND

Velocity 1: 3276, Velocity 2: 3255, Velocity 3: 3279

Accuracy = 2.293" @ 300 Yards.

Load two: 96.0 RETUMBO with the 180 ACCUBOND

Velocity 1: 3351, Velocity 2: 3352, Velocity 3: 3375

Accuracy = 3" @ 300 Yards.

Second 300 Yard Session

It was now time to re-test the best load.

Load notes:

Load one: 95.0 RL-25 with the 180 ACCUBOND

Velocity 1: 3485, Note that the bolt was stuck and had to be tapped open. There was a major extractor mark and cratered primer. Velocity 2: 3437, note that extraction was easier but sticky. Extractor mark as well. Velocity 3: 3395, note that the extraction was easier yet but still a bit sticky.

Accuracy = 3" @ 300 Yards.

Load two: 96.0 H1000 with the 180 ACCUBOND

Velocity 1: 3345, Velocity 2: 3316, Velocity 3: 3301

Accuracy = 2.155" @ 300 Yards.

Load three: 96.5 H-1000 with the 180 ACCUBOND

Velocity 1: 3373, Velocity 2: 3344, Velocity 3: 3380

Accuracy = 2.082" @ 300 Yards.

It is noted that this load was hot due to slightly sticky extraction and ejector marks.

Load four: 90.0 H-1000 with the 180 E-Tip

Velocity 1: 3238, Velocity 2: 3227, Velocity 3: 3218

Accuracy = 3" @ 300 Yards.

Something is not right

This certainly isn't the end of my development, but there are enough load notes above to gauge the overall performance of this rifle. It is at about this stage that I feel like something dramatic is wrong. It seems as if my pressures are going up with the same loads from day to day. I start dropping powder charges lower and lower and they still seem hotter and hotter. Also it starts to copper foul really bad. After a total of between 200 and 250 rounds fired, the barrel settles down and pressures and velocity appear to become consistent.

Now I start the load development over. To make a very long story short, this rifle will no longer shoot the 200 ACCUBOND with any degree of accuracy and no matter what powder or the charge weight, extraction is tough and the brass is beat up. I have fired it with H50 BMG with as little as 3000 FPS and the extraction and brass are not good. I have also tried using RL-25 and H1000 with even more horrid results. The 180 ACCUBOND doesn't act as bad but acts very similar to the 200. Now after its settle down mode, the loads it likes the best is the 220 SMK over 90.0 H50 BMG at 2850 FPS, the 208 AMAX with 93.0 H50 BMG at 2925 FPS, the 190 Hornaday BTSP atop with 88.5 grains of RL25 and the 178 AMAX with 90.0 H-1000. All will hold .5 MOA or better with the 220, 208, 178, especially the 208 doing so the best. The 190 averages 0.5 to 0.6 MOA and sometimes does better and sometimes hits the 1 MOA mark.

My Worst Fears Are Realized

I took my barrel to a local smith the other day along with the old Lilja barrel I still have that has over 1000 rounds through her. I compared the throat of each side by side as well as several inches up the barrel. To my surprise, the ABS looks almost identical to the Lilja with not even half as many rounds through it. At this point, it become clear as to why it copper fouls so bad now and won't shoot the same as it did in the beginning with the same loads. I only had between 60-65 shots through it when I noticed the major changes. The throat was somewhat cooke

Article Tools

- Overall Impressions Of the 300 Rum and ABS Barrel

First, The Barrel

Overall, the rifle shoots a few loads pretty decent even with a cooked throat and heat cracks several inches up the barrel. The barrels may hold up much better with smaller cartridges, but that remains to be seen. All I really ended up with was a barrel that fit my existing stock channel that didn't weigh as much. I think that what I will do, since what is done is done, is use this rifle for a 1300 yard sheep, deer, goat and antelope rifle. Since it really shines with the 208 AMAX, and this bullet is perfect for up to big mule deer size critters, this is what it will be summoned to do.

After upgrading scope bases and rings, the total rifle with scope and bipod weighs in at around 12 pounds. This is my comfort level for a back country rifle. So even though I feel I could do better with a different barrel, this one will work more than adequately for anything I am going to ask of it, so long as I stop all development and move to using it only when needed.

After the above writings, I contacted Mike at ABS and explained the problems I have had with the barrel. He invited me to ship it back to him and he would examine the barrel. If there was a problem, he said he would replace the it. I sent him the barrel and he bore scoped it, Rockwell tested it, re-lapped it and scoped it again. After lapping it and scoping it, he decided to offer me a brand new barrel.

He couldn't explain the problems as he just hadn't seen anything like it. He was honest and said he didn't have an answer as to what was going on. He did say that the Rockwell test came back with perfect results. So the steel was fine. After he offered me a new barrel, I asked him if I could go with a different caliber. After having two different brands in the same chambering with similar results, I decided to move on to something that would last a bit longer. He said no problem. He would cut me anything I wanted. I had always wanted to play with the 338 Edge and asked him about boring the .308 out to .338 out, since it was cut rifle barrel and the steel was perfect and I was supremely happy with the chamber. Then if it didn't shoot well, then he could invest in a brand new one for me. Why risk getting a substandard piece of steel or a less than perfect chamber? I already had those things.

He agreed to bore it out so we could test it. After getting the barrel back, I bore scoped it and found that it was a good looking bore. It was a wee bit "rough" but that was due to the limited lapping you can do with a bore that is already crowned and chambered. I allowed for a break-in period to see if it would "smooth" out. I installed it, and had a break-in session. After 17 or 18 shots she started to clean up extremely well. In fact, about the easiest I have ever cleaned a barrel. Another look through the bore scope revealed that it was very smooth and crisp with NO heat cracks or any burned throat.

During break in, when I got to the part of shooting up to 3 rounds between cleanings, the first group at 300 yards was promising and the second was 7/8" at 300 yards! That is promise. I started developing using H1000 and the 250 SMK. She seemed to hold .5 MOA. I decided to take her to 700 yards and it held about .75 MOA for the most part in some awful wind. One group was 1.5" at 700 yards! Once I got some 300 grain Scenars; things really looked up. She started shooting in the .2's at 100 yards and held sub half MOA at 300 yards. I cannot argue with that.

So far it has been one of the sweetest shooting rifles I have owned yet. It seems very easy to tune loads, has very low extreme spreads and is very accurate. After exceeding the 100 round count, I bore scoped it again and it looks the same as It did in the beginning. Perfect. There was not one single heat crack and no burned areas of the throat. It truly looks brand new. Albeit I let the barrel cool between every shot, and I am not running super hot loads. I will admit I was skeptical of boring out a barrel. But after the results I have been getting, I am very glad I went with it. Mike D. at ABS really is a stand up guy. He was ready to give me a brand new barrel after examining it and still would if this one didn't shoot well. I wouldn't be caught dead trying to get rid of this barrel!

Now, The Caliber

My overall impression of the 300 RUM is mostly positive. In standard air it can easily deliver a very well constructed bullet capable of expansion at 1000+ yards, as well as deliver over 1360 foot pounds of energy. It can also deliver higher BC bullets of less stout construction capable of expansion well under the 1600 FPS mark, with nearly 1500 foot pounds of energy at 1000 yards. In the accuracy department, both my barrels showed that they can run with the best of any hunting rifle. While short of benchrest standards, they were more than adequate for long range shooting and hunting. Both shot under .25 MOA on their best days and seldom shot 1 MOA and even more rarely, over 1 MOA. Usually if there was a 1 MOA or over 1 MOA group, it was during some developmental or experimental stage. My only gripes with the 300 RUM are barrel life, cost of operation and recoil, which is manageable even for a recoil sensitive shooter like myself but I still don't classify it as mild. At least not at 12#. When it was 16.5#, it was very mild to me.

Again, after the above writings and some time behind the 338 Edge, I can honestly say that barrel life looks much better for the bigger bore. With the added "reach" of the 300 grain pills over the 30 caliber variety and better barrel life I cannot see myself ever looking back to the 300 RUM. The recoil did go up a bit, but not as much as I had anticipated. The other benefits more than make up for the bit of added recoil. The accuracy potential of this caliber seems better than average. Maybe I should rephrase that comment and say that this caliber does not seem finicky as it is very easy to tune and even the "bad" loads are sub minute. All in all, I am VERY happy with both the rifle and the caliber.

Michael Eichele has lived in Alaska for 10 years. He has killed 4 Dall rams. The largest was 38" long with 14 1/2" bases. The longest was 763 yards.