The Over-Rated Crown

By Alan Marshall

You probably think having a perfect crown is important to accuracy. I think so too … although this article will make you wonder.

Background: I was told that one of the major chronograph manufacturers checked the velocities of the rifles of three officers so they could determine their come-ups for various ranges. The rifles were described as being similar, as was the ammo. What was interesting was that the bullet's Ballistic Coefficient (BC) when fired from Rifle 1 was different than the bullet's BC from Rifle 2 and from Rifle 3. In fact, each rifle could be distinguished by the BC it produced. (As an aside – Was the rifle with the highest BC also the most accurate?) So the question is - What caused the difference? It wasn't the ammo, since the same ammo was used in all three rifles, and it wasn't the shooter. It must have been the rifle, but what part of the rifle? My first thought was that maybe the crowns were a little different, perhaps by cleaning rod wear or a less than perfect crown to begin with. It made sense to me that a perfect crown would allow the bullet to start its flight with very little yaw, resulting in the highest BC possible for that particular bullet. On the other hand, a crown that is off center or has a ding in it would allow gas to exit non-uniformly and thus kick the base of the bullet a little to one side as it left the muzzle, resulting in a wobbling bullet with greater drag and a lower BC.

To see if the crown was the problem we borrowed a retired .308 Winchester Model 70, with a 24" heavy barrel and a muzzle diameter of .78". We figured that if we started with a good crown, recorded the BC and then damaged the crown and recorded a lower BC, that would confirm that at least with one rifle the change in BC could be attributable to crown condition. I looked at the crown under the stereo microscope (10X) and found that the edge was slightly rounded over instead of having a nice crisp edge. That would have to be touched up in order to participate in our experiment. We had John recrown the barrel using the Brownells' Manson muzzle crown refacing kit. This kit didn't require taking the barreled action out of the McMillan stock, and the 11° crown that he cut looked great under the stereo microscope. We set up the Oehler M83 system, the Oehler 57 Chronograph Sky Screens (set at 15 feet), the Oehler acoustic target (set at 100 yards) and the Phantom v7.3 high speed video. The acoustic target measures the down range velocity, time of flight, BC and the group size. The rifle had a 3.5-10X Leupold scope. I set the rifle on a Sinclair front rest and a Protector rear bag. The ammo was Federal .308 Gold Medal Match 175 grain Sierra Matchking, GMM308M2, all from the same lot. The ammo was not sorted by weight, concentricity or anything else. It was straight from the box. I started with a five shot group from the 'perfect' crown. At this point I'll throw out an excuse regarding my group sizes. I like shooting orange dots. Unfortunately, the dot I put out was the right size for a 20X scope but too small to quarter with the 10X. So I just lined up the crosshairs until the dot pretty much disappeared under the intersection of the crosshairs and pulled the trigger. The groups might have been a little bit smaller if I hadn't been too lazy to dig out a bigger dot, but to be honest I expected the accuracy to go to pot after the first group so I wasn't too concerned with wringing out the last bit of accuracy. I expected .75 MOA accuracy with the good crown and four or five MOA accuracy by the time we were done destroying the crown.

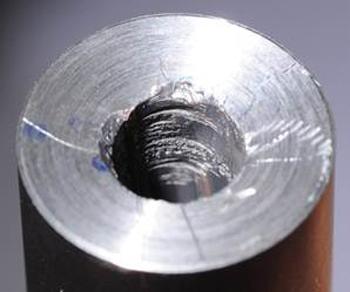

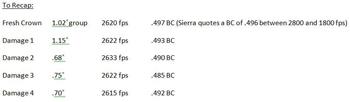

The first five round group, with a perfect crown, measured 1.020". The velocity recorded fifteen feet in front of the muzzle averaged 2620 fps, with a Standard Deviation (SD) of 10 (.4%). The Ballistic Coefficient (BC) was .497, SD of .008 (1.6%). Just a comment on the BC – the velocity varies from shot to shot and the BC varies even more! For these five shots the BC varied from .486 to .509. It makes you wonder why BCs are listed to the thousandths place when they vary at the hundredths place. I used to be under the impression that the BC was a set number and only the muzzle velocity varied shot to shot, but as you can see, the BC varied more as a percentage than did the muzzle velocity. Further, I didn't always believe the published BC for some bullets (thinking that the bullet maker might be guilty of a wee bit of BC exaggeration), but I believed that whatever the BC was, it would be the same for each shot unless there was obvious damage to the bullet nose. I'd be interested to know, and will try this when I have a chance, if polygon barrels will yield higher BCs than conventionally rifled barrels since the bullet's bearing surface should be smoother than it would have been if cut into by the lands of a conventionally rifled barrel. Regarding group sizes listed here, the Oehler Acoustic Target measures groups by using 4 microphones set in a 24" square. As the bullet passes through the interior of the square, each microphone hears the crack of the bullet's mach cone at slightly different times. The machine uses this data to determine the bullet's horizontal and vertical position and plots it on a graph on the computer screen. I didn't trust it at first, and always compared the computer target to the paper target, but eventually the computer won me over. The system works and it works quite well.

As another example of BC variability I compared a Berger VLD to a Hornady A-Max on the same day, using the same rifle and testing equipment, and at the same altitude, temperature, pressure and humidity. Any set-up errors were the same for both sets of bullets. The Berger's BCs for three shots were .523, .526 and .540. The Hornady's BCs were .552, .545 and .541. You might conclude that the plastic tipped bullets are more consistent than those without but I've seen some very consistent TSX bullets, for example. Three rounds of the .308 110 grain Barnes TSX had BCs of .268, .269 and .267, but the group was 1.29". On the other hand the .308 168 grain Matchking had BCs of .450, .459 and .469 but had a group of .41". The most widely varying BCs I have observed were with some jacketed soft point .22 caliber centerfire bullets. In one ten shot string, the BCs varied from .141 to .200. Apparently some tips were flattened more than others during manufacturing or loading and this change in meplat diameter (measuring .097" to .114" ̎) affected the BC. This meplat diameter variability causes the BC to vary more with small calibers than with large(r) calibers. Having said all that, a uniform meplat doesn't guarantee a uniform BC.

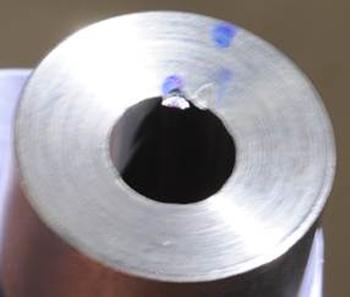

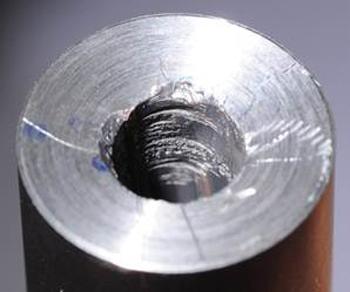

Following group one I used a MotoTool cut-off wheel to cut a small notch in a groove in the crown at twelve o'clock. (See Photo 1) We expected to see some gases venting up and perhaps the bullet nose tipping down as viewed in the Phantom, but it wasn't visible.

Photo 1 – small notch located in a groove at 12 o'clock

The velocity averaged 2622 fps, SD 14 (.5%). The BC was .493, SD .007 (1.4%). The group was 1.152", primarily vertical. Maybe the 12 o'clock damage was inducing some up and down movement.

That wasn't so bad, maybe I can do better. I took a pin punch and a hammer and punched a burr into the bore on one of the lands. The first shot broke off the burr and launched it out of the barrel. A small copper colored cloud was briefly visible, possibly from the jacket impacting the burr. The group was .676", the velocity averaged 2633 fps, SD 15 (.6%), and the BC was .490, SD .007 (1.4%). (See Photo 2)

Photo 2 – shows a burr punched onto the land to the left of the notch shown in Photo One. Sorry it's blurry … must have been the earthquake.

OK, no more Mister Nice Guy. Time for the carbide burr. I made a half moon cut out at the crown. It resulted in a .751" group, a velocity of 2622 fps, SD 7 (.3%), and a BC of .485, SD .008 (1.6%). I hate to say it, but it's almost like the crown doesn't matter. Nah, couldn't be!

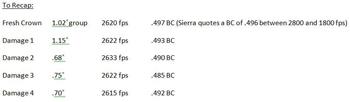

Mr. Beaufort thought I was being too gentle, so he tried his hand at a little precision gun plumbin'. He wallered that carbide burr around the crown and down inside the barrel to a depth of maybe half an inch. I've never broken a carbide burr in a barrel, but I'm here to say it can be done. He also breaks the heads off scope base screws. And after he participated in a USMC shotgun endurance test, the Marines, not generally considered pansies, told him that he was hard on their guns. Applying that same enthusiasm, he made an absolute mess of the last half inch of the barrel. We concluded that any hopes of accuracy were now gone. (See Photo 3)

Photo 3 – What happens when you go wild with a carbide burr. The criminal responsible for this indignity will never be allowed near a Bartlein or Krieger again.

They were… at least for the next two shots, which made a group of 1.740". This group is heading South. Wait – keep shooting. The next five rounds made a group of .697". The velocity for those seven rounds averaged 2615 fps, SD 8 (.3%), and the BC was .492, SD .007 (1.4%).

Somebody want to explain these results? How can a barrel with a crown that has been absolutely destroyed shoot under ¾ MOA? Beats me. I saw it and I still don't believe it. Well I do believe it because I saw it, but I can't explain it. And since I can't explain it I am going to continue to insist on having as perfect a crown as is possible. But if I ever see a guy shorten a barrel with a hacksaw, knock off the sharp edges with a file and crown it with an RCBS case mouth chamfering tool, I don't think I'll tell him that it won't shoot. I'll just wait and see.

By the way, I ran an unpaired t test to compare the BC means (averages) and found that the difference between the 'Fresh crown' BC and the 'Damage 4' BC is considered to be not statistically significant at 95% confidence.

… Weeks pass and the earth turns. This still doesn't make sense. Since this doesn't make sense I must be coming up with the wrong answers or else I haven't asked the right questions. Here's a Q and A that I've heard and believe – What is the last part of the barrel to touch the bullet before it takes flight? Answer – the crown. So with a Q and A like that, the obvious conclusion is the belief that the crown must be perfect to have perfect bullet flight. Maybe that's a good question but not the best question. Or maybe that's a good question for rimfires but not so important with jacketed bullets. So what other questions should I ask? Maybe there are other factors that I should have considered.

The rifles were described as being similar. Maybe they were all Remington 700s in .308. Maybe there was a 20" LTR with three flutes and a 1:12 twist, a 24" SPS with a 1:10 twist and a 700P with a 26" 1:12 twist heavy barrel. If the LTR had a 'slow' barrel that had been shot a lot and the 700P had a new 'fast' barrel, the muzzle velocities could be far enough apart to affect the BC. If the ammo utilized was Remington loaded 168 grain Sierra Matchkings at 2680 fps and the BC was determined over 100 yards, the BC for the first half of its flight would be in the upper range (>2600 fps = .462 BC, < 2600 fps = .447 BC) for the long barrel. The LTR velocity would start below 2600 fps and would thus be in the .447 BC range for the entire 100 yards. The barrel length difference alone could account for the BC differences noted between two of these three rifles. But what if all three rifles had the same barrel length?

I attended an NDIA Conference where Jeff Siewert of Arrow Tech Associates (of PRODAS(1) fame) had a booth. He sent me a presentation titled "Factors Affecting Small Caliber Dispersion"(2). He pointed out that "small caliber bullets in high pressure systems operate at stress levels above projectile material yield stress". So at 60,000 psi that bullet starts acting like putty in the barrel. "Deformed projectile shape may not be symmetric" and "orientation of in-bore angle and CG (center of gravity) offset varies shot-to-shot". I think there are a couple of implications here. If the throat is oval and/or non-concentric with the bore and/or perfectly cylindrical but oversized, as the bullet turns to putty, it is going to conform to the throat's diameter and shape right before it gets swaged back down to bore size. During these transitions the bullet is deformed from its original perfect (?) shape and this deformation may not be symmetric. As an example, if the reamer cuts the chamber off center to the bore by .003" and the loaded ammo concentricity varies by .003", then you could have errors that add to or cancel each other out. Also, if the reamer is off center then the lands will be cut further down the barrel on one side compared to the other. (So your jam length would be measured to the first land, not to all the lands.) When that happens, the land closest to the chamber will become the first speed bump the bullet hits, will slow the bullet on that side and try to make it tip. Strong ejector tension can tip the cartridge and its bullet in the chamber (more in a sloppy chamber than a tight chamber). Depending on the orientation of the closest land to the direction of tip, the closest land can increase or decrease the tendency to tip. It's possible that the shooters that believe in barrel indexing are experimenting, at least partially, with this effect when testing factory barrels.

Don't expect the bore to correct chamber and throat problems. I have looked at recovered bullets that had land impressions that are longer on one side of the bullet than on the other. That means that the bullet was tipped (the in-bore angle was not zero) as it went down the barrel and that the bullet nose was tracing a helix as it moved down the barrel. The longer the boattail and the longer the nose, the shorter the bearing surface. The shorter the bearing surface, the greater the likelihood that the bullet can tip inside the barrel. (A VLD can tip more in the barrel than a wadcutter bullet). The implication here is that I may have been looking at the wrong end of the barrel to explain the BC change among the three officer's rifles. Maybe the crowns were all good but the throats or chambers were different. Or maybe the throat differences plus the crown differences combined to make the BC changes so noticeable. If the throat was oversized then the bullet could tip as it left the cartridge case and the in-bore yaw could continue the length of the barrel. Of course if throat condition is the great question and crown condition is the good question, that's going to be a real pain in the neck since it's relatively easy to look at the crown but looking at the throat is not as easy.

Jeff discussed some Internal Dispersion Factors that could have had an influence in the three barrel test. Let me say up front that I don't assume that all the factors that contribute to changes in BC also contribute to inaccuracy, but I think that some of the factors overlap. In any case, they're interesting to consider. The bullet's geometry, mass properties and radial stiffness are assumed to be the same since the ammo was the same. Bullet run-out could be a problem, but again it should have been the same across the board. So gun-to-gun differences are prime considerations. These would include, although some don't apply:

"Barrel flexural properties (bending & hoop stiffness)" - "The gun barrel diameter grows elastically in response to internal pressurization with the OD influencing ID growth". "The projectile tips in the bore due to the ID growth". In other words, the max heavy contour will 'grow' less, both externally and internally, as the bullet goes down the barrel compared to a sporter contour barrel, and it will also bend less. As the barrel ID expands, the bullet has a greater chance to tip. Add to this that some factory bores have tight and loose spots in them which allow the bullet to tip inside the oversized sections and once the tipping (yaw) has begun it can continue the length of the barrel. "The projectile tilt, CG offset and spin during early in-bore travel drives barrel transverse motion."(3)

"Bore Straightness" - I can confirm, having shortened a few barrels, that some bores are shaped like a banana. I say that based on the fact that the crown was centered originally but after cutting the barrel shorter the new muzzle crown was no longer centered within the OD of the barrel. I think this would affect the accuracy more than the BC, especially as the barrel heats up.

"Engraving variations" - I know that many shooters have issues with bullet coatings, but Jeff had an interesting Engraving Force Variation graph. Comparing Push Force Standard Deviation in kN versus InBore Travel in mm, the coated Barnes 168 BT showed much less variation than the uncoated Barnes 168 BT.(4)

"Muzzle Blast / Base pressure at Muzzle Exit"(5) - Lower pressure on the base of the bullet is considered a good thing, so longer barrels are better than short barrels in this regard. Bullets continue to accelerate for several inches past the muzzle as the high pressure muzzle blast gas continues to push on the base of the bullet without the friction of the bore to slow it (the bullet) down. High pressure on the base of the bullet, especially if the bullet was canted in the bore and therefore canted at exit, won't help accuracy and could also increase bullet wobble and decrease its BC. As an aside, I chronographed a suppressed rifle the other day and found that with the suppressor attached, the velocity dropped about 10 fps compared to its velocity without the suppressor. That was unexpected, as suppressors often increase the velocity by 10 or 15 fps. Apparently this last suppressor did a better job of slowing and stripping away the muzzle blast gas, thus robbing the bullet of its normal muzzle blast acceleration.

"In-bore clearance"(6) - The "projectile body is nominal interference fit with lands, but elastic deflection of bore due to internal pressurization allows the projectile to tip in-bore relative to bore centerline." This effect can be more pronounced on looser barrels. I slugged one of my Remington .308 barrels and the slug measured .3085 ̎across the grooves. Compare that to a Krieger barrel that measure .3065 ̎ across the grooves. The tighter barrel should reduce in-bore clearance. Random orientation of projectile in-bore angle applies loads to the barrel which affect barrel pointing and cross velocity at muzzle exit."(7)

Solid bullets shoot smallest dispersion with .050"- .080" free run while conventional drawn copper jacket / lead core bullets shoot smallest dispersion with .015"- .030" free run.(8) My take on this is that if you are limited to magazine length ammo but have a factory barrel with a long throat, solid bullets, such as the Barnes TSX, Hornady GMX and Nosler E-tip, could provide better accuracy since they tolerate being further from the lands. Example – if your magazine is 2.85" long and your jam length is 2.92" long, the .070" difference is quite a jump for conventional cup and core bullets but is just right for the all copper / gilding metal bullets.

Getting back to the crown and the three rifle BC variation - I'm afraid I ended up with more questions than answers. If I had to guess, I think that the throat dimensions would be worth checking out if the barrel lengths and contours were all similar.

Conclusion: Having a perfect crown is an absolute requirement for pinpoint accuracy ... unless it isn't.

(1) PRODAS stands for PROjectile Design and Analysis System. Arrow Tech Associates are located at 1233 Shelburne Road, Suite D-8, S. Burlington, VT 05403

(2) Jeff Siewert, Arrow Tech Associates Inc., May 2010, National Defense Industrial Association Joint Armament Powerpoint presentation, page 3

(3) Ibid, page 18

(4) Ibid, page 17

(5) Ibid, page 4

(6) Ibid, page 6

(7) Ibid, page 7

(8) Ibid, page 23

By Alan Marshall

You probably think having a perfect crown is important to accuracy. I think so too … although this article will make you wonder.

Background: I was told that one of the major chronograph manufacturers checked the velocities of the rifles of three officers so they could determine their come-ups for various ranges. The rifles were described as being similar, as was the ammo. What was interesting was that the bullet's Ballistic Coefficient (BC) when fired from Rifle 1 was different than the bullet's BC from Rifle 2 and from Rifle 3. In fact, each rifle could be distinguished by the BC it produced. (As an aside – Was the rifle with the highest BC also the most accurate?) So the question is - What caused the difference? It wasn't the ammo, since the same ammo was used in all three rifles, and it wasn't the shooter. It must have been the rifle, but what part of the rifle? My first thought was that maybe the crowns were a little different, perhaps by cleaning rod wear or a less than perfect crown to begin with. It made sense to me that a perfect crown would allow the bullet to start its flight with very little yaw, resulting in the highest BC possible for that particular bullet. On the other hand, a crown that is off center or has a ding in it would allow gas to exit non-uniformly and thus kick the base of the bullet a little to one side as it left the muzzle, resulting in a wobbling bullet with greater drag and a lower BC.

To see if the crown was the problem we borrowed a retired .308 Winchester Model 70, with a 24" heavy barrel and a muzzle diameter of .78". We figured that if we started with a good crown, recorded the BC and then damaged the crown and recorded a lower BC, that would confirm that at least with one rifle the change in BC could be attributable to crown condition. I looked at the crown under the stereo microscope (10X) and found that the edge was slightly rounded over instead of having a nice crisp edge. That would have to be touched up in order to participate in our experiment. We had John recrown the barrel using the Brownells' Manson muzzle crown refacing kit. This kit didn't require taking the barreled action out of the McMillan stock, and the 11° crown that he cut looked great under the stereo microscope. We set up the Oehler M83 system, the Oehler 57 Chronograph Sky Screens (set at 15 feet), the Oehler acoustic target (set at 100 yards) and the Phantom v7.3 high speed video. The acoustic target measures the down range velocity, time of flight, BC and the group size. The rifle had a 3.5-10X Leupold scope. I set the rifle on a Sinclair front rest and a Protector rear bag. The ammo was Federal .308 Gold Medal Match 175 grain Sierra Matchking, GMM308M2, all from the same lot. The ammo was not sorted by weight, concentricity or anything else. It was straight from the box. I started with a five shot group from the 'perfect' crown. At this point I'll throw out an excuse regarding my group sizes. I like shooting orange dots. Unfortunately, the dot I put out was the right size for a 20X scope but too small to quarter with the 10X. So I just lined up the crosshairs until the dot pretty much disappeared under the intersection of the crosshairs and pulled the trigger. The groups might have been a little bit smaller if I hadn't been too lazy to dig out a bigger dot, but to be honest I expected the accuracy to go to pot after the first group so I wasn't too concerned with wringing out the last bit of accuracy. I expected .75 MOA accuracy with the good crown and four or five MOA accuracy by the time we were done destroying the crown.

The first five round group, with a perfect crown, measured 1.020". The velocity recorded fifteen feet in front of the muzzle averaged 2620 fps, with a Standard Deviation (SD) of 10 (.4%). The Ballistic Coefficient (BC) was .497, SD of .008 (1.6%). Just a comment on the BC – the velocity varies from shot to shot and the BC varies even more! For these five shots the BC varied from .486 to .509. It makes you wonder why BCs are listed to the thousandths place when they vary at the hundredths place. I used to be under the impression that the BC was a set number and only the muzzle velocity varied shot to shot, but as you can see, the BC varied more as a percentage than did the muzzle velocity. Further, I didn't always believe the published BC for some bullets (thinking that the bullet maker might be guilty of a wee bit of BC exaggeration), but I believed that whatever the BC was, it would be the same for each shot unless there was obvious damage to the bullet nose. I'd be interested to know, and will try this when I have a chance, if polygon barrels will yield higher BCs than conventionally rifled barrels since the bullet's bearing surface should be smoother than it would have been if cut into by the lands of a conventionally rifled barrel. Regarding group sizes listed here, the Oehler Acoustic Target measures groups by using 4 microphones set in a 24" square. As the bullet passes through the interior of the square, each microphone hears the crack of the bullet's mach cone at slightly different times. The machine uses this data to determine the bullet's horizontal and vertical position and plots it on a graph on the computer screen. I didn't trust it at first, and always compared the computer target to the paper target, but eventually the computer won me over. The system works and it works quite well.

As another example of BC variability I compared a Berger VLD to a Hornady A-Max on the same day, using the same rifle and testing equipment, and at the same altitude, temperature, pressure and humidity. Any set-up errors were the same for both sets of bullets. The Berger's BCs for three shots were .523, .526 and .540. The Hornady's BCs were .552, .545 and .541. You might conclude that the plastic tipped bullets are more consistent than those without but I've seen some very consistent TSX bullets, for example. Three rounds of the .308 110 grain Barnes TSX had BCs of .268, .269 and .267, but the group was 1.29". On the other hand the .308 168 grain Matchking had BCs of .450, .459 and .469 but had a group of .41". The most widely varying BCs I have observed were with some jacketed soft point .22 caliber centerfire bullets. In one ten shot string, the BCs varied from .141 to .200. Apparently some tips were flattened more than others during manufacturing or loading and this change in meplat diameter (measuring .097" to .114" ̎) affected the BC. This meplat diameter variability causes the BC to vary more with small calibers than with large(r) calibers. Having said all that, a uniform meplat doesn't guarantee a uniform BC.

Following group one I used a MotoTool cut-off wheel to cut a small notch in a groove in the crown at twelve o'clock. (See Photo 1) We expected to see some gases venting up and perhaps the bullet nose tipping down as viewed in the Phantom, but it wasn't visible.

Photo 1 – small notch located in a groove at 12 o'clock

The velocity averaged 2622 fps, SD 14 (.5%). The BC was .493, SD .007 (1.4%). The group was 1.152", primarily vertical. Maybe the 12 o'clock damage was inducing some up and down movement.

That wasn't so bad, maybe I can do better. I took a pin punch and a hammer and punched a burr into the bore on one of the lands. The first shot broke off the burr and launched it out of the barrel. A small copper colored cloud was briefly visible, possibly from the jacket impacting the burr. The group was .676", the velocity averaged 2633 fps, SD 15 (.6%), and the BC was .490, SD .007 (1.4%). (See Photo 2)

Photo 2 – shows a burr punched onto the land to the left of the notch shown in Photo One. Sorry it's blurry … must have been the earthquake.

OK, no more Mister Nice Guy. Time for the carbide burr. I made a half moon cut out at the crown. It resulted in a .751" group, a velocity of 2622 fps, SD 7 (.3%), and a BC of .485, SD .008 (1.6%). I hate to say it, but it's almost like the crown doesn't matter. Nah, couldn't be!

Mr. Beaufort thought I was being too gentle, so he tried his hand at a little precision gun plumbin'. He wallered that carbide burr around the crown and down inside the barrel to a depth of maybe half an inch. I've never broken a carbide burr in a barrel, but I'm here to say it can be done. He also breaks the heads off scope base screws. And after he participated in a USMC shotgun endurance test, the Marines, not generally considered pansies, told him that he was hard on their guns. Applying that same enthusiasm, he made an absolute mess of the last half inch of the barrel. We concluded that any hopes of accuracy were now gone. (See Photo 3)

Photo 3 – What happens when you go wild with a carbide burr. The criminal responsible for this indignity will never be allowed near a Bartlein or Krieger again.

They were… at least for the next two shots, which made a group of 1.740". This group is heading South. Wait – keep shooting. The next five rounds made a group of .697". The velocity for those seven rounds averaged 2615 fps, SD 8 (.3%), and the BC was .492, SD .007 (1.4%).

Somebody want to explain these results? How can a barrel with a crown that has been absolutely destroyed shoot under ¾ MOA? Beats me. I saw it and I still don't believe it. Well I do believe it because I saw it, but I can't explain it. And since I can't explain it I am going to continue to insist on having as perfect a crown as is possible. But if I ever see a guy shorten a barrel with a hacksaw, knock off the sharp edges with a file and crown it with an RCBS case mouth chamfering tool, I don't think I'll tell him that it won't shoot. I'll just wait and see.

By the way, I ran an unpaired t test to compare the BC means (averages) and found that the difference between the 'Fresh crown' BC and the 'Damage 4' BC is considered to be not statistically significant at 95% confidence.

… Weeks pass and the earth turns. This still doesn't make sense. Since this doesn't make sense I must be coming up with the wrong answers or else I haven't asked the right questions. Here's a Q and A that I've heard and believe – What is the last part of the barrel to touch the bullet before it takes flight? Answer – the crown. So with a Q and A like that, the obvious conclusion is the belief that the crown must be perfect to have perfect bullet flight. Maybe that's a good question but not the best question. Or maybe that's a good question for rimfires but not so important with jacketed bullets. So what other questions should I ask? Maybe there are other factors that I should have considered.

The rifles were described as being similar. Maybe they were all Remington 700s in .308. Maybe there was a 20" LTR with three flutes and a 1:12 twist, a 24" SPS with a 1:10 twist and a 700P with a 26" 1:12 twist heavy barrel. If the LTR had a 'slow' barrel that had been shot a lot and the 700P had a new 'fast' barrel, the muzzle velocities could be far enough apart to affect the BC. If the ammo utilized was Remington loaded 168 grain Sierra Matchkings at 2680 fps and the BC was determined over 100 yards, the BC for the first half of its flight would be in the upper range (>2600 fps = .462 BC, < 2600 fps = .447 BC) for the long barrel. The LTR velocity would start below 2600 fps and would thus be in the .447 BC range for the entire 100 yards. The barrel length difference alone could account for the BC differences noted between two of these three rifles. But what if all three rifles had the same barrel length?

I attended an NDIA Conference where Jeff Siewert of Arrow Tech Associates (of PRODAS(1) fame) had a booth. He sent me a presentation titled "Factors Affecting Small Caliber Dispersion"(2). He pointed out that "small caliber bullets in high pressure systems operate at stress levels above projectile material yield stress". So at 60,000 psi that bullet starts acting like putty in the barrel. "Deformed projectile shape may not be symmetric" and "orientation of in-bore angle and CG (center of gravity) offset varies shot-to-shot". I think there are a couple of implications here. If the throat is oval and/or non-concentric with the bore and/or perfectly cylindrical but oversized, as the bullet turns to putty, it is going to conform to the throat's diameter and shape right before it gets swaged back down to bore size. During these transitions the bullet is deformed from its original perfect (?) shape and this deformation may not be symmetric. As an example, if the reamer cuts the chamber off center to the bore by .003" and the loaded ammo concentricity varies by .003", then you could have errors that add to or cancel each other out. Also, if the reamer is off center then the lands will be cut further down the barrel on one side compared to the other. (So your jam length would be measured to the first land, not to all the lands.) When that happens, the land closest to the chamber will become the first speed bump the bullet hits, will slow the bullet on that side and try to make it tip. Strong ejector tension can tip the cartridge and its bullet in the chamber (more in a sloppy chamber than a tight chamber). Depending on the orientation of the closest land to the direction of tip, the closest land can increase or decrease the tendency to tip. It's possible that the shooters that believe in barrel indexing are experimenting, at least partially, with this effect when testing factory barrels.

Don't expect the bore to correct chamber and throat problems. I have looked at recovered bullets that had land impressions that are longer on one side of the bullet than on the other. That means that the bullet was tipped (the in-bore angle was not zero) as it went down the barrel and that the bullet nose was tracing a helix as it moved down the barrel. The longer the boattail and the longer the nose, the shorter the bearing surface. The shorter the bearing surface, the greater the likelihood that the bullet can tip inside the barrel. (A VLD can tip more in the barrel than a wadcutter bullet). The implication here is that I may have been looking at the wrong end of the barrel to explain the BC change among the three officer's rifles. Maybe the crowns were all good but the throats or chambers were different. Or maybe the throat differences plus the crown differences combined to make the BC changes so noticeable. If the throat was oversized then the bullet could tip as it left the cartridge case and the in-bore yaw could continue the length of the barrel. Of course if throat condition is the great question and crown condition is the good question, that's going to be a real pain in the neck since it's relatively easy to look at the crown but looking at the throat is not as easy.

Jeff discussed some Internal Dispersion Factors that could have had an influence in the three barrel test. Let me say up front that I don't assume that all the factors that contribute to changes in BC also contribute to inaccuracy, but I think that some of the factors overlap. In any case, they're interesting to consider. The bullet's geometry, mass properties and radial stiffness are assumed to be the same since the ammo was the same. Bullet run-out could be a problem, but again it should have been the same across the board. So gun-to-gun differences are prime considerations. These would include, although some don't apply:

"Barrel flexural properties (bending & hoop stiffness)" - "The gun barrel diameter grows elastically in response to internal pressurization with the OD influencing ID growth". "The projectile tips in the bore due to the ID growth". In other words, the max heavy contour will 'grow' less, both externally and internally, as the bullet goes down the barrel compared to a sporter contour barrel, and it will also bend less. As the barrel ID expands, the bullet has a greater chance to tip. Add to this that some factory bores have tight and loose spots in them which allow the bullet to tip inside the oversized sections and once the tipping (yaw) has begun it can continue the length of the barrel. "The projectile tilt, CG offset and spin during early in-bore travel drives barrel transverse motion."(3)

"Bore Straightness" - I can confirm, having shortened a few barrels, that some bores are shaped like a banana. I say that based on the fact that the crown was centered originally but after cutting the barrel shorter the new muzzle crown was no longer centered within the OD of the barrel. I think this would affect the accuracy more than the BC, especially as the barrel heats up.

"Engraving variations" - I know that many shooters have issues with bullet coatings, but Jeff had an interesting Engraving Force Variation graph. Comparing Push Force Standard Deviation in kN versus InBore Travel in mm, the coated Barnes 168 BT showed much less variation than the uncoated Barnes 168 BT.(4)

"Muzzle Blast / Base pressure at Muzzle Exit"(5) - Lower pressure on the base of the bullet is considered a good thing, so longer barrels are better than short barrels in this regard. Bullets continue to accelerate for several inches past the muzzle as the high pressure muzzle blast gas continues to push on the base of the bullet without the friction of the bore to slow it (the bullet) down. High pressure on the base of the bullet, especially if the bullet was canted in the bore and therefore canted at exit, won't help accuracy and could also increase bullet wobble and decrease its BC. As an aside, I chronographed a suppressed rifle the other day and found that with the suppressor attached, the velocity dropped about 10 fps compared to its velocity without the suppressor. That was unexpected, as suppressors often increase the velocity by 10 or 15 fps. Apparently this last suppressor did a better job of slowing and stripping away the muzzle blast gas, thus robbing the bullet of its normal muzzle blast acceleration.

"In-bore clearance"(6) - The "projectile body is nominal interference fit with lands, but elastic deflection of bore due to internal pressurization allows the projectile to tip in-bore relative to bore centerline." This effect can be more pronounced on looser barrels. I slugged one of my Remington .308 barrels and the slug measured .3085 ̎across the grooves. Compare that to a Krieger barrel that measure .3065 ̎ across the grooves. The tighter barrel should reduce in-bore clearance. Random orientation of projectile in-bore angle applies loads to the barrel which affect barrel pointing and cross velocity at muzzle exit."(7)

Solid bullets shoot smallest dispersion with .050"- .080" free run while conventional drawn copper jacket / lead core bullets shoot smallest dispersion with .015"- .030" free run.(8) My take on this is that if you are limited to magazine length ammo but have a factory barrel with a long throat, solid bullets, such as the Barnes TSX, Hornady GMX and Nosler E-tip, could provide better accuracy since they tolerate being further from the lands. Example – if your magazine is 2.85" long and your jam length is 2.92" long, the .070" difference is quite a jump for conventional cup and core bullets but is just right for the all copper / gilding metal bullets.

Getting back to the crown and the three rifle BC variation - I'm afraid I ended up with more questions than answers. If I had to guess, I think that the throat dimensions would be worth checking out if the barrel lengths and contours were all similar.

Conclusion: Having a perfect crown is an absolute requirement for pinpoint accuracy ... unless it isn't.

(1) PRODAS stands for PROjectile Design and Analysis System. Arrow Tech Associates are located at 1233 Shelburne Road, Suite D-8, S. Burlington, VT 05403

(2) Jeff Siewert, Arrow Tech Associates Inc., May 2010, National Defense Industrial Association Joint Armament Powerpoint presentation, page 3

(3) Ibid, page 18

(4) Ibid, page 17

(5) Ibid, page 4

(6) Ibid, page 6

(7) Ibid, page 7

(8) Ibid, page 23