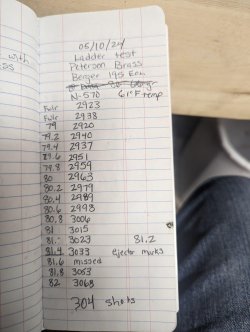

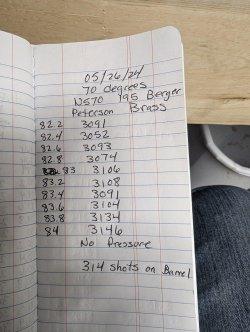

So got my die set up and properly going. The forming bushing are in .025 steps...starts out at .475 down to .309. I did figure out annealing is a bad idea until after 3 steps of necking down.. nuked the case in my amp annealer..after that I just annealed every other stage. One thing I did different this go around after having weird things happen to the neck and shoulder (moving around unexpectedly) is I trimmed to 2.855 after the neck down to .350. (When it'd fit in my Rockford trimmer). I also didn't set shoulders to my fired cases dimension since it's got "steps" in it and looks almost like a weatherby case...I did first one long and just bumped shoulder back untill I could close the bolt with slight resistance...almost like a Ackley fit. I also got the idea to fireform cases with pistol powder and coffee grounds. 12 gr titegroup,paper towel barrier, filled with used espresso coffee grounds from my wife's crack...coffee habit. Then another layer of paper towel wad to seal...these formed better than fireforming the first batch with a mild load and bullet..never did this before but after much scientific research (googled the **** out of it) I decided this route was worth a shot instead of sending rounds down a limited life barrel...first trial shot was in the garage with my 13 yr old son standing watch for the dragon/wife or the cops...pointed the rifle at a sheet of plywood backed by cement board, held on tight, squeezed the trigger and hoped I didn't blow my nuts off somehow. Decent "Pop!" And I had a perfect stw case formed exactly how I wanted it. We would have gotten away with it too but the boy ratted me out...needless to say wifezilla was not happy about rifles being touched off in the garage so now Im just gonna do it at the range if I need to again...and a certain boy was told snitches get stitches. I'm gonna try to make it to the range in next couple of days and work up a ladder to see the top end of the brass. Will report my findings on the Peterson vs nosler brass.