I am shooting a Remington 722 in Cal .244 Remington (6mm) with 75 gr. V MAX bullets I am thinking of restocking this rifle and would like to put a stock on it that handles the minimal recoil better so that it would aid in the ability to witness the bullet hits. What stock design might that be ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stock Design

- Thread starter cappi

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

James Jones

Well-Known Member

- Joined

- Jul 1, 2002

- Messages

- 2,854

A heavy one !! No but realy their is no way that you cankeep a gun from recoiling completely even a 40lb 22-250 is gonna move some its just life.

But a gun that has a bit more weight toward the front like with heavy barrels and longer foredns that are wide and heavy will allow you to controle the recoil better. The actual desgine of the stock will have little to do with your ability to spot hits as long as the stock fits you well.

I assume that your gun has a heavy barrel? if not then add some weight to the stock to help hold it still.

Thebest way to be able to spot your hits is with a brake , the brake will wipe out alot of that recoil and jump from the gun. Shooting 140gr bullet from my 260 at close to 2900fps I can spot my hits at 300yds , probably 200 if I could train my eye to stay focused through the noise of the gun going off and its due to a heavy gun and great brake.

But a gun that has a bit more weight toward the front like with heavy barrels and longer foredns that are wide and heavy will allow you to controle the recoil better. The actual desgine of the stock will have little to do with your ability to spot hits as long as the stock fits you well.

I assume that your gun has a heavy barrel? if not then add some weight to the stock to help hold it still.

Thebest way to be able to spot your hits is with a brake , the brake will wipe out alot of that recoil and jump from the gun. Shooting 140gr bullet from my 260 at close to 2900fps I can spot my hits at 300yds , probably 200 if I could train my eye to stay focused through the noise of the gun going off and its due to a heavy gun and great brake.

royinidaho

Well-Known Member

Cappi,

I'm a stickler for spotting my shot also. I was able to do it with a 270 Win in a Fajen thumbhole stock. The stock was straighter than a pool cue. Recoil was straight back.

When I moved into long range hunting I wanted the same capability with the 270 Allen Mag and 338 Rum. I shoot 170 gr bullets in the 270 and 300 SMKs in the 338. I can pretty much spot all shots with the Allen Mag and when the setup is 'just right' the same goes for the 338, especially the looonnnggg shots with the RUM.

My thinking was carried over a bit from my bench rest days so I looked at several bench rest designs. I didn't like the McMillan A-5 for two reasons; 1) Everybody and their brother had one and 2) I didn't like the grip prefering the trigger pull feel being straight back to the thumb of the thumb hole. The A-5 does that also but it isn't what I prefer for a grip.

The stocks on both rifles were sporter designs which didn't cut the mustard.

My idea was line of bore parallel with all bearing surfaces, forearm, bottom of butt and cheek weld. Plus the top of the butt stock being the proper height for the scope to get a very light cheek weld.

I searched the web and found Shehane Tracker stocks to be quite attractive. » Target Stocks NightForce Scopes Nightforce NXS Rifle Scopes : Custom Rifle Stocks for Benchrest Shooting

At that site I saw what is called the Modified Lee Six Thumbhole Tracker and decided on that design in a NY minute. The pluses are the straight flat surfaces, the 2" longer fore end (looks better with the 30" bbl and moves the bipod ahead that two inches. Another plus is the ability to shoot left or right handed. Who knows when that will be needed, but it will and is needed from time to time.

So with all of this in mind I made my own or, to be truthful, modified the Bell and Carlson carbalite sporter stock as I wanted to maintain the pillar/skim bedding that Kirby did. Also this was the quickest way that I could develop the pattern for copies of the stock for other rifles which will be modified for their specific use.

This is what I ended up with and it works very well.

Before:

After:

Gussied up a bit:

I'm a stickler for spotting my shot also. I was able to do it with a 270 Win in a Fajen thumbhole stock. The stock was straighter than a pool cue. Recoil was straight back.

When I moved into long range hunting I wanted the same capability with the 270 Allen Mag and 338 Rum. I shoot 170 gr bullets in the 270 and 300 SMKs in the 338. I can pretty much spot all shots with the Allen Mag and when the setup is 'just right' the same goes for the 338, especially the looonnnggg shots with the RUM.

My thinking was carried over a bit from my bench rest days so I looked at several bench rest designs. I didn't like the McMillan A-5 for two reasons; 1) Everybody and their brother had one and 2) I didn't like the grip prefering the trigger pull feel being straight back to the thumb of the thumb hole. The A-5 does that also but it isn't what I prefer for a grip.

The stocks on both rifles were sporter designs which didn't cut the mustard.

My idea was line of bore parallel with all bearing surfaces, forearm, bottom of butt and cheek weld. Plus the top of the butt stock being the proper height for the scope to get a very light cheek weld.

I searched the web and found Shehane Tracker stocks to be quite attractive. » Target Stocks NightForce Scopes Nightforce NXS Rifle Scopes : Custom Rifle Stocks for Benchrest Shooting

At that site I saw what is called the Modified Lee Six Thumbhole Tracker and decided on that design in a NY minute. The pluses are the straight flat surfaces, the 2" longer fore end (looks better with the 30" bbl and moves the bipod ahead that two inches. Another plus is the ability to shoot left or right handed. Who knows when that will be needed, but it will and is needed from time to time.

So with all of this in mind I made my own or, to be truthful, modified the Bell and Carlson carbalite sporter stock as I wanted to maintain the pillar/skim bedding that Kirby did. Also this was the quickest way that I could develop the pattern for copies of the stock for other rifles which will be modified for their specific use.

This is what I ended up with and it works very well.

Before:

After:

Gussied up a bit:

NesikaChad

Well-Known Member

I've stocked a few guns and my first question for anyone is this:

What is your intended application?

Is this a bench gun, a bag gun, a tac rifle, position shooting, prone?

That would need to be answered first.

There are stocks out there though that do provide better tracking from a bag or bi pod so that one may observe a bullets flight through the scope all the way to the target.

Thumbholes work but I personally don't advocate them in anything but a single shot. It's just a kick in the sack when trying to manipulate a bolt quickly on a repeater. That's my opinion anyways.

-Always nice to have when spending an afternoon in a prairie dog town. . .

What is your intended application?

Is this a bench gun, a bag gun, a tac rifle, position shooting, prone?

That would need to be answered first.

There are stocks out there though that do provide better tracking from a bag or bi pod so that one may observe a bullets flight through the scope all the way to the target.

Thumbholes work but I personally don't advocate them in anything but a single shot. It's just a kick in the sack when trying to manipulate a bolt quickly on a repeater. That's my opinion anyways.

-Always nice to have when spending an afternoon in a prairie dog town. . .

Last edited:

royinidaho

Well-Known Member

What is your intended application?

Is this a bench gun, a bag gun, a tac rifle, position shooting, prone?

I'd be interested in your thoughts, I'm open to new ideas, anytime.

My intended use is sniping critters from a hide, prone. All of my rifles are single shot except for the lonesome 222 Rem yote, call/walk-stalk gun.

I can't see the vapor trail as the rifles jitter a bit but if I control my blink the target is in the scope the whole time.

Thanks in advance.

The more specific information that you need is this . I want to use the Hornady 75gr. VMAX or occasionally the 85 gr VMAX bullets in a Remington 6mm rifle. One rifle is a Remington 722 in cal. .244 with 26 " barrel . I also have a Rem.700 BDL in cal. 6mm with a 24 " bull barrel. The primary use for either of these rifles is prarie dog or woodchuck hunting. The goal is to observe the hit. I would restock either rifle to redirect the energy given off by the 75 or 85 grain 6 MMs if that is part of the solution.I am also willing to put a muzzle brake on the barrel if anyone can recommend one that works ,based on EXPERIENCE. Also I kind of like the way that i can hold on to the thumbhole stocks and am not too concerned about how fast i can get off a second shot at the" usually" now running chuck. PS. All shots will be taken from a portable bench or attached bi-pod from the ground.

Last edited:

NesikaChad

Well-Known Member

Stocks and noise makers

Stocks.

Ok, wood or synthetic?

I advocate either one. Makes not one bit of difference if the gun is done right.

Bill Shehane does a good job with his laminates, I've used several during my tenure with Nesika.

The big stocks from McMillan work just as well.

If you call Nesika and ask for Mr. Richard Spruill you may still be able to obtain a "Nesika Varmint" stock made up with a fairly unique laminate called "Fibron."

If you want a stock with some mass, this is the way to go.

I have a 22-250 done up this way and I can literally watch the bullet go down range all the way to the target. Not the trace, I mean the bullet itself. (32X on the bags @ 100 yards in the COR-BON ammunition tunnel.)

They won't be inletted or finish sanded on the outside so it'll take a bit of work to get it done up.

Thats just another option for ya to consider.

What I've learned to do on bag guns is to fiddle with how the action sits in the stock. It's taboo in most circles to orientate the action in any fashion other than dead nuts parallel with the stocks "water line". On bag guns I've taken to the practice of just ever so slightly elevating the muzzle so that the barreled action is essentially "ramping up" and out of the stock as you go towards the crown.

This is a well versed "trick" in bench circles as many feel it aids in how the gun tracks in the bags.

It's so subtle that the casual observer really won't even notice it.

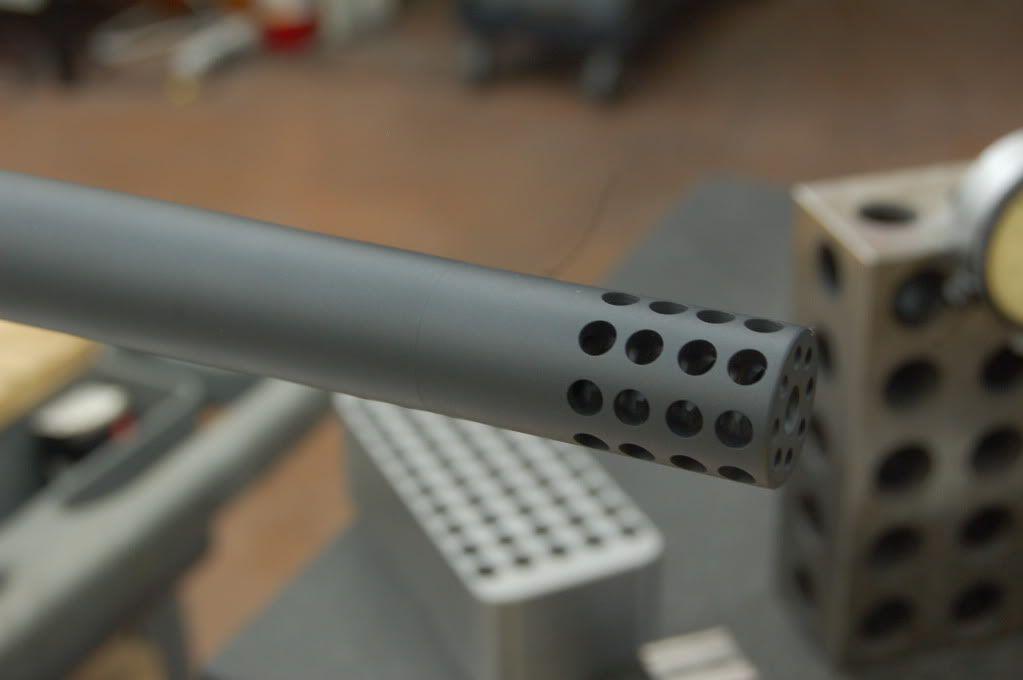

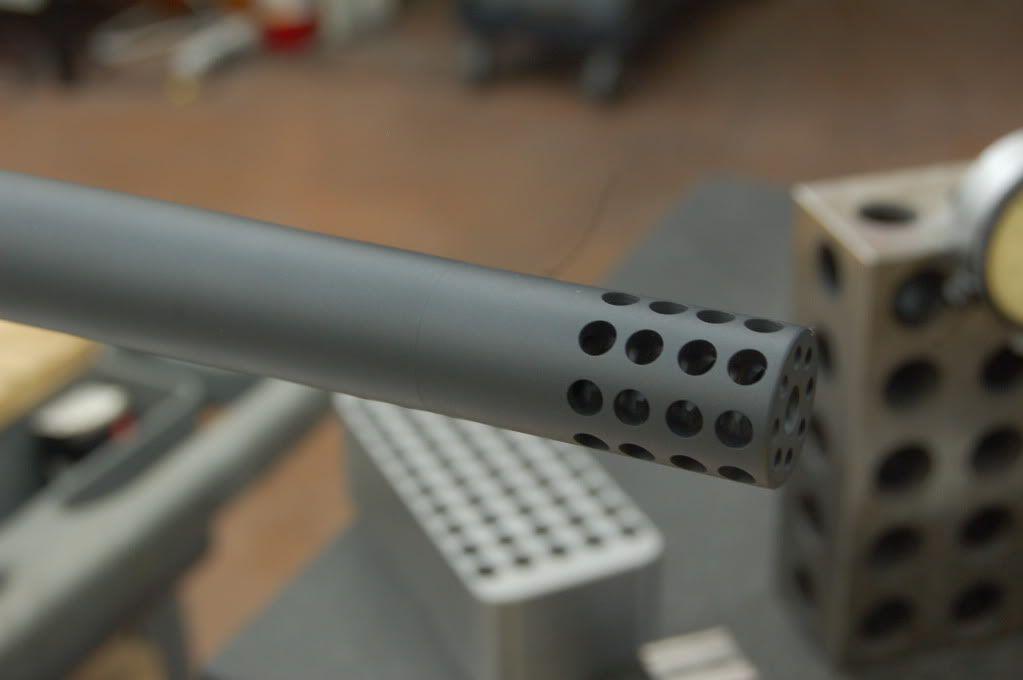

As far as muzzle brakes goes:

I've installed and shot a lot of Vaise brakes. They work well at taming a savage beast. This is what I used on my 22-250, 300-338 Lapua Magnum, and my 338 Lapua Magnum. I have no complaints. If you go this route one word of caution. Be **** sure the person installing it understands how they are made. You go turning the OD past the minimum dimension documented in the instructions and you will "ventilate" the brake and ruin it. The outer holes running parallel to the bore's axis are what I'm talking about.

Experience is never cheap. I'll leave it at that.

I've also designed a brake that is used on the Dakota Arms Scimitar tactical rifle. It's not very exciting as far as brakes go, but it does work well enough. It also helps to reduce (not eliminate) the signature of the gun. Those big boomers create a pretty good dust print.

The brake itself isn't the novelty, its how its made that is pretty cool. The vents are machined with the brake "blank" threaded and torqued onto the barrel. This way you index the barrel in the machine and you know for sure that your clocking is dead nuts. Nothing reeks of "Rookie Night" more to me than a muzzle brake rotated off at some retarded angle.

Anyways. . .

Another thing to consider is having one (or more) slush tubes installed in the back of the stock. They do help to deaden the level of movement in the gun during recoil. Other "tricks" that I've done is to add lead to the forend under the barrel. I once machined a pocket feature and just mixed up lead shot with acra glass and poured it in the pocket and allowed it to cure. Then I finish machined the barrel channel and capped it all off by laminating a couple sheets of carbon fiber twill weave cloth right along the whole length of the forend.

Nothing adds to the "bling" factor quite like carbon. Customers get all giddy over that stuff.

So, there's a few ideas regarding stocks and brakes.

Good luck, hope this helped.

. . .and no, that scope is not touching the barrel /\. I promise!

Stocks.

Ok, wood or synthetic?

I advocate either one. Makes not one bit of difference if the gun is done right.

Bill Shehane does a good job with his laminates, I've used several during my tenure with Nesika.

The big stocks from McMillan work just as well.

If you call Nesika and ask for Mr. Richard Spruill you may still be able to obtain a "Nesika Varmint" stock made up with a fairly unique laminate called "Fibron."

If you want a stock with some mass, this is the way to go.

I have a 22-250 done up this way and I can literally watch the bullet go down range all the way to the target. Not the trace, I mean the bullet itself. (32X on the bags @ 100 yards in the COR-BON ammunition tunnel.)

They won't be inletted or finish sanded on the outside so it'll take a bit of work to get it done up.

Thats just another option for ya to consider.

What I've learned to do on bag guns is to fiddle with how the action sits in the stock. It's taboo in most circles to orientate the action in any fashion other than dead nuts parallel with the stocks "water line". On bag guns I've taken to the practice of just ever so slightly elevating the muzzle so that the barreled action is essentially "ramping up" and out of the stock as you go towards the crown.

This is a well versed "trick" in bench circles as many feel it aids in how the gun tracks in the bags.

It's so subtle that the casual observer really won't even notice it.

As far as muzzle brakes goes:

I've installed and shot a lot of Vaise brakes. They work well at taming a savage beast. This is what I used on my 22-250, 300-338 Lapua Magnum, and my 338 Lapua Magnum. I have no complaints. If you go this route one word of caution. Be **** sure the person installing it understands how they are made. You go turning the OD past the minimum dimension documented in the instructions and you will "ventilate" the brake and ruin it. The outer holes running parallel to the bore's axis are what I'm talking about.

Experience is never cheap. I'll leave it at that.

I've also designed a brake that is used on the Dakota Arms Scimitar tactical rifle. It's not very exciting as far as brakes go, but it does work well enough. It also helps to reduce (not eliminate) the signature of the gun. Those big boomers create a pretty good dust print.

The brake itself isn't the novelty, its how its made that is pretty cool. The vents are machined with the brake "blank" threaded and torqued onto the barrel. This way you index the barrel in the machine and you know for sure that your clocking is dead nuts. Nothing reeks of "Rookie Night" more to me than a muzzle brake rotated off at some retarded angle.

Anyways. . .

Another thing to consider is having one (or more) slush tubes installed in the back of the stock. They do help to deaden the level of movement in the gun during recoil. Other "tricks" that I've done is to add lead to the forend under the barrel. I once machined a pocket feature and just mixed up lead shot with acra glass and poured it in the pocket and allowed it to cure. Then I finish machined the barrel channel and capped it all off by laminating a couple sheets of carbon fiber twill weave cloth right along the whole length of the forend.

Nothing adds to the "bling" factor quite like carbon. Customers get all giddy over that stuff.

So, there's a few ideas regarding stocks and brakes.

Good luck, hope this helped.

. . .and no, that scope is not touching the barrel /\. I promise!

Last edited:

royinidaho

Well-Known Member

NesikaChad,

Its said that when you raise the tide you raise all of the boats.

You just raised all the boats about a foot, (Except for the ones with holes in the bottom ) and that's a bunch.

) and that's a bunch.

Thanks for sharing your experience.

Roy

Its said that when you raise the tide you raise all of the boats.

You just raised all the boats about a foot, (Except for the ones with holes in the bottom

Thanks for sharing your experience.

Roy

NesikaChad

Well-Known Member

Roy thanks for the kind words but its obvious we've never met.

If ya'll are in boats, most who know me would agree then that I'm out bobbing around in a life preserver off in my own little world. . .

Anyways, appreciate the remarks.

Cheers.

If ya'll are in boats, most who know me would agree then that I'm out bobbing around in a life preserver off in my own little world. . .

Anyways, appreciate the remarks.

Cheers.