Ok. So I have a sue that is there sometimes and not others. I am loading 28 nosler with 155 hh. Using retumbo powder. I had hard bolt retract not lift at 86 gr. Using new adg brass. I cleaned tumbled full length sized the brass and ram it again at 84 and 84.5 grain. Had hard extract on all of them. This is through a fierce carbon fury. Has anybody else run into this with this rifle or with the brass. I think I have a problem but haven't narrowed it down to brass ,chamber, or possibly resizing die it's a Redding. Any body else have some thoughts on this?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolt stick

- Thread starter Gills

- Start date

Help Support Long Range Hunting Forum

Help Support Long Range Hunting Forum

Hard to retract bolt could be caused by a larger diameter portion of the chamber. Take a fired case and cover it with a sharpie and place it back in the chamber. When it is removed look for areas where the ink is rubbed off. Could be an area where the chamber diameter is larger causing the fireformed case to enlarge to conform which will have resistance to removal. Repair? Fix chamber. Sometimes all it takes is some mild sanding. If it is severe, I would be talking to the manufacturer.

lancetkenyon

Well-Known Member

Yes. The AHs are a bore rider, meaning the drive bands are at caliber, but the main bullet shank diameter is undersized.From their website- "You will see that these bullets will require faster than normal powders for the cartridge and bullet weight. Load with caution."

Absolute Hammer bullet, different then Hunting?

https://www.longrangehunting.com/threads/hammer-hunter-load-data-see-page-1-post-8.273018/

Use to much powder & high pressure is the results.

Use to much powder & high pressure is the results.

Attachments

Seabeeken

Well-Known Member

The times i had a hard extraction issue it turned out to be high pressure and the head expanded and was gripping the chamber. Backed off the load and all was fine. This happened with alpha 6.5 creed brass reformed to 250ai. Didnt take much to stick in the tight chamber. Switched to 22-250 lapua brass and no more issues

I get the pressure thing that was my first thought but after dropping the grains by three I would think I had gotten away from that aspect. Why would once fired full length sized have pressure after two grain drop in charge when they didn't get pressure in first firing until 86. Already tried turning sizing die in a bit more no difference. These are 155 gr hammer hunters not absolute hammers and according to hammer bullets build less pressure than other standard bullets.

MagnumManiac

Well-Known Member

Because once fired brass DOES NOT expand like unfired brass which acts like a "cushion" hiding the overpressure load.

Back off and start again…

Cheers.

Back off and start again…

Cheers.

Might very well be over pressure, but first thing I'd be checking is to make sure you bumped the shoulders back far enough on resizing. Measure the new, unfired brass with the proper shoulder bump gauge (for Whidden it would be a .420 sbg) make sure you are bumping back to within .002 of new when you resize. If you didn't bump it back far enough it would be tight on chambering and extraction. Have you tried chambering an empty, resized piece of brass to make sure it feeds easily?

The 86 grs may have expanded the web area of the brass. May not spring back if pressure was above 76,000 PSI. The expanded area will drag on the chamber, possible causing hard extraction?Why would once fired full length sized have pressure after two grain drop in charge when they didn't get pressure in first firing until 86.

Looking at data for lighter, different bullets, 84 gr may still cause high pressure?

Are there any other pressure signs? On case head from the ejector cut out on the bolt face?

Primer flow into firing pin hole?

Your bullet is 155 gr, bearing surface may be a lot longer then bullets in above data. Heavier too.

Hard to measure with all the pressure reducing cuts.

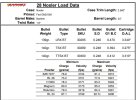

143 HH -86.5 grs-3650 fps.

140 TTSX-84.4 grs-3391 fps

Big Difference in velocity.

Pressue and velocity is dependent on length of bearing surface.

If there is no published data for a combination of components, we can only guess at the PSI.

Hard to measure with all the pressure reducing cuts.

143 HH -86.5 grs-3650 fps.

140 TTSX-84.4 grs-3391 fps

Big Difference in velocity.

Pressue and velocity is dependent on length of bearing surface.

If there is no published data for a combination of components, we can only guess at the PSI.

QuietTexan

Well-Known Member

All you've done with that is create more shoulder/chamber clearance and likely overwork your brass. Take a step back, set up your sizing die correctly, and re-run the pressure test in fired brass. Adjusting the sizing die vertically does not drastically change how the sizing die sizes the case walls like it does the shoulders. If you end up needing more body sizing than your die is giving you (making the assumption the Redding die you are using is an FL die) you'll need a different die.Already tried turning sizing die in a bit more no difference.

The size of new brass has no relation to what you should be sizing brass to. To ensure case fit in the chamber the case should be sized some amount less than where the round won't rechamber in your rifle. -0.002" is a commonly given spec for moving shoulders back, but only in relation to a fully formed case.make sure you are bumping back to within .002 of new when you resize

Similar threads

- Replies

- 94

- Views

- 76K