Given the 195g LRHT bearing surface is 0.063" longer than the 180VLDH, to keep the start of the boat tail at the same point relative to the base of the shoulder vs the 180vld with a 0.190" FB it would require the FB for the 195g to be 0.253". Seems like a lot to me especially given the 7PRC which is really optimized for the 180/195g class bullets has a 0.233" FB. Some simple calculations given the brass dimensions will get you close but I'd go the route of doing as others have suggested with creating a dummy round. The art is trying to get the base of the boat tail above the neck shoulder junction while still allowing enough neck engagement on the bullet and room to chase the lands.

TL: DR version: If you want only the boat tail of a 195 Berger below the neck, you will need a custom chamber with freebore that extends to at least 2.381" from the bolt face. The loaded cartridge will be over 3.25" long. If you don't mind more of the bullet inside the case, a less extreme chamber will work, but the COAL will still be about 3" to keep the ogive out of the neck.

Background:

I got curious and did a deep dive on reamers and chambers for this cartridge and ran some calculations. In the end, it comes down to which bullets are likely to be used and if the chamber should be optimized for an unusually long one like the 195 Berger Extreme Outer Limits. It also matters if you want the all bullet's bearing surface in front of the shoulder-neck junction or whether you are fine with some of the shank below the neck and in the powder area. On top of that, there is the question of how much jump would be best.

Nit-picky Confusing Details :

Unfortunately, the term "freebore" has several definitions and this can cause confusion. In this post, what matters is the distance from the mouth of a chambered, max-spec case to the spot where the interior of the barrel becomes the same diameter as the bullet's full-diameter bearing surface. This is where the bullet has an interference fit and "jams" in the barrel.* I will use the term "effective total freebore" to describe this dimension.

A typical reamer cuts some clearance in front of the case neck and a chamfer from the neck diameter to the start of the tapered throat ( for the SAAMI WSM spec) or freebore tube + throat combination (on cartridges like the 7mm PRC, Rem Mag, RSAUM, etc). That freebore tube is slightly larger than the bullet diameter, so the bullet travels an additional short distance past it before reaching an interference fit inside the barrel.

With the 7mm PRC, for example, the total "effective freebore" is about 0.272". Given the clearance and chamfer, the length of the .2846" dia freebore-tube shown on the chamber drawing is 0.233", as noted by KsKevin.

The bullet's full-diameter bearing surface jams about 2.552" from bolt face, if my math is correct**. The geometry of the bullet's ogive may change that a tiny bit. This gives a jump to the lands of about 0.034" if the 195 Berger is loaded with its boattail-shank junction in line with the case's shoulder-neck junction (1.9932" from bolt face). This should give a loaded COAL of about 3.391" (longer than the SAAMI spec of 3.34").

With the 7mm WSM, the max case length is 2.10". The 195 Berger has a bearing surface length of 0.524", a 0.25" boattail, a 0.874" nose (ogive), and a length of 1.648". With the beginning of the boattail at the shoulder-neck junction of the case (1.8565" from the bolt face), the COAL will be about 3.255". The bearing surface on the bullet would end about 2.381" from the bolt face. To "jam into the lands", the effective total freebore will be about 0.281". The length of a freebore tube (0.2845"dia) would be roughly 0.242" long, given a fairly standard 0.01" clearance in front of the case, a 45° chamfer and a 0.01" distance from the end of the freebore-tube to the the jam-point in the barrel.

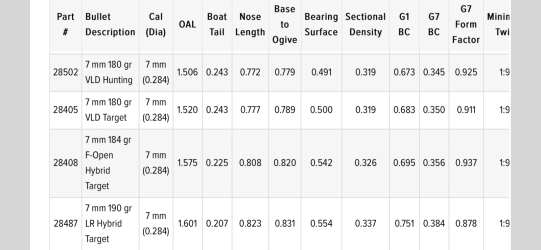

The Berger Hybrids do not need to be jammed into the lands for accuracy, which brings up the question of lengthening the freebore section for additional jump. I have seen a drawing for a reamer from JGS designed for the "180 Berger", which I think is the 180 grain VLD Hunting bullet. The notes state it gives the bullet a 0.036" jump. This particular reamer had a total effective freebore of about 0.279" and the 0.2845" diameter freebore tube was 0.240" long, ending at 2.3688" from the bolt. My estimates for a chamber using the 180's specs with a 0.036" jump are within 0.01" of this reamer print, so I think my reasoning is sound. FWIW, the 195 Berger's bearing surface is about .033" longer than the 180 VLD's 0.491".

I will post the reamer print if I get permission to do so.

* To make matters more confusing, this is not always the start of the rifling since some cartridges like the 7mm WSM spec a groove diameter (0.2837") which is smaller than the typical .284" bullet. That means the bullet's bearing surface will jam before encountering the rifling.

** The case mouth (max) is 2.28" from the bolt face. The end of the 0.2846" dia freebore-tube is at 2.540". The distance from the end of the freebore-tube to the place where the bullet's .284" dia bearing surface jams in the barrel is about 0.012" farther given the 1.5° slope per side in the tapered throat (or forcing cone... the term used by Hornady in their podcasts).