I finally got around to shooting this load last week at 100yds.

Conditions were ok. Temperature in the high 60's, with winds varying 8-15 mph from about 130 degrees. This didn't bother me, as I was shooting for velocity, not group size.

In summary, I loaded the following:

Kimber 84L Classic 30-06 with 24" bbl

Leupold 3-9X40

RL26

WLR Primers

180gr Nosler Partition P/N 16331

New Starline Brass with post firing avg case capacity 70.2 at 2.485" case length

COAL 3.294". (0.010" off lands)

Magnetospeed Sportster

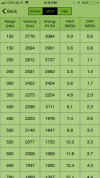

Shot# Gr FPS

53 61gr 2866

54 61.5gr 2879

55 62gr 2893

56 62.5gr 2905

57 63gr 2925

58 63.5gr 2952

Even though I didn't see any pressure signs on the brass/primer, and no heavy bolt lift, I decided not to shoot the 64 and 64.5gr loads. Primers were a little flat, but were actually the same looking at all charge weights and also looked the same from some mild 165gr H4350 loads I shot also.

I'm pretty impressed with the results. Also the 4 shot group from 62, 62.5, 63, and 63.5 gr was right around 1" - which shows a lot of promise regarding the POI change over such a large range of charge weights/velocities.

I'm going to focus on 62-63.4 gr in 0.2gr increments, with 5 shots each to see which shoots the best with respect to group size and ES.

According to my QL runs, the 63.5 gr load is right at 60kpsi at 2952 fps.

The 64gr load is estimated at 62kpsi, and the 64.5gr load would be 64kpsi at 2999 fps. Absolutely smokin' for a 30-06. For this modern 30-06, I'm sure both of those would be fine - but I see no reason to push it as my goal of 2900 fps was initially met and exceeded.

Note: Bottom row is the RL26/180 Partition

The first thing I plan to shoot with this load is a crow, in order to make a pie for some of you doubters.