Hugnot

Well-Known Member

Prelim results, looking good for rodents.

Accuracy needs to be tuned, about .5 MOA.

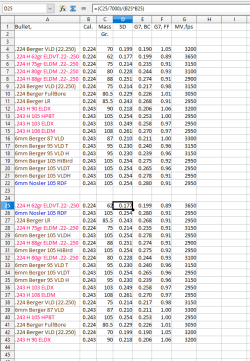

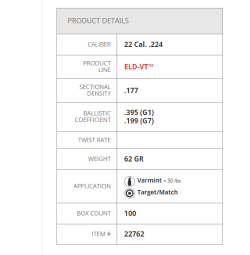

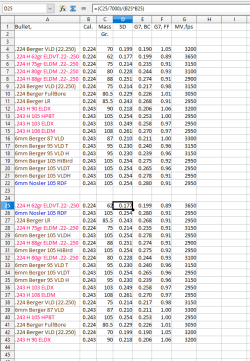

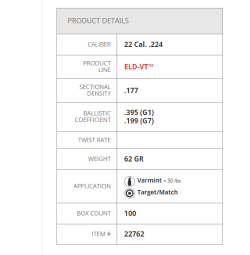

Among best for FF, hi vel from 7.7 twist .22-.250 @ 3637 fps, table at bottom is sorted on FF column. Hi vel capability, low drag, light weight.

Accuracy needs to be tuned to equal that of 75 ELDM in my rifles

7.7 twist works but 9 twist in .223 @ 3,000 fps was total failure.

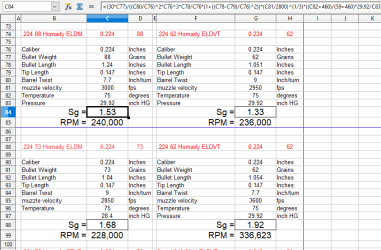

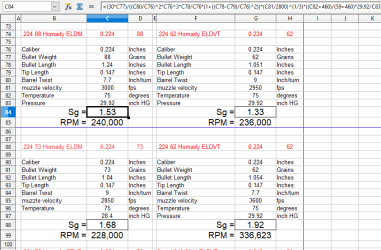

Look at the X-section of the 62 ELDVT, large void, compared to the X-section of the 73 ELDM no void.

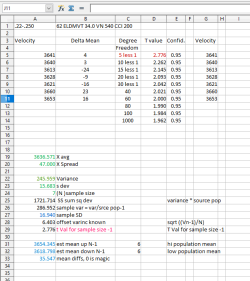

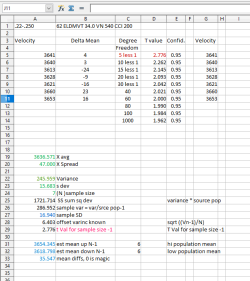

My guess is the diff between center of mass & pressure don't fit that good for the Miller method. A Sg of 1.3 should provide adequate stability for reasonable accuracy but my 9 twist .223 failed to group at 100 & no bullet failure, like gray smoke.

.75 MOA up from 200 yard zero on target at 300, nice extended point blank range on small targets.

(I like to use lots of paragraphs)

Accuracy needs to be tuned, about .5 MOA.

Among best for FF, hi vel from 7.7 twist .22-.250 @ 3637 fps, table at bottom is sorted on FF column. Hi vel capability, low drag, light weight.

Accuracy needs to be tuned to equal that of 75 ELDM in my rifles

7.7 twist works but 9 twist in .223 @ 3,000 fps was total failure.

Look at the X-section of the 62 ELDVT, large void, compared to the X-section of the 73 ELDM no void.

My guess is the diff between center of mass & pressure don't fit that good for the Miller method. A Sg of 1.3 should provide adequate stability for reasonable accuracy but my 9 twist .223 failed to group at 100 & no bullet failure, like gray smoke.

.75 MOA up from 200 yard zero on target at 300, nice extended point blank range on small targets.

(I like to use lots of paragraphs)

Last edited: